silicone sealant making machine

1. Introduction

A. Basic material production system: Put the 103 glue and other material into the Kneading machine, operating with Heat transfer oil heating system and Vacuum system.

B. Basic material milling system: After the Basic material production system, use a Pump to transfer the material into the Three-roll milling machine, and get the semi-finished sealant.

C. Silicone sealant making system: Add other raw materials, colors and mix with the semi-finished sealant in the Dispersing machine, and then can get the finished silicone sealant.

D. Packing system: Using the Hydraulic pressing machine to press out the silicone sealant, and the packing by the Bottle-type filling machine or Sausage-type filling machine.

2. Usage

A. Neutral Silicone Sealant: used for filling and sealing in metal, glass, mirror, glass window, aluminium products, PMMA, silicone resin, vulcanizing silicone rubber, ceramics, natural and synthetic fiber, concrete, cement, marble, steel, etc.

B. Acid Silicone Sealant: used for filling and sealing in all kinds of interior decoration of car, nameplate, plastic material, pipe joints, glass, glass window, etc.

3. Production process

Step 1: Kneading machine, Three-roll milling machine

Step 2: Dispersion mixer, Hydraulic pressing machine

Step 3: Bottle-type filling machine (Semi-automatic filling machine)

Step 4: Sausage-type filling machine (Automatic filling machine)

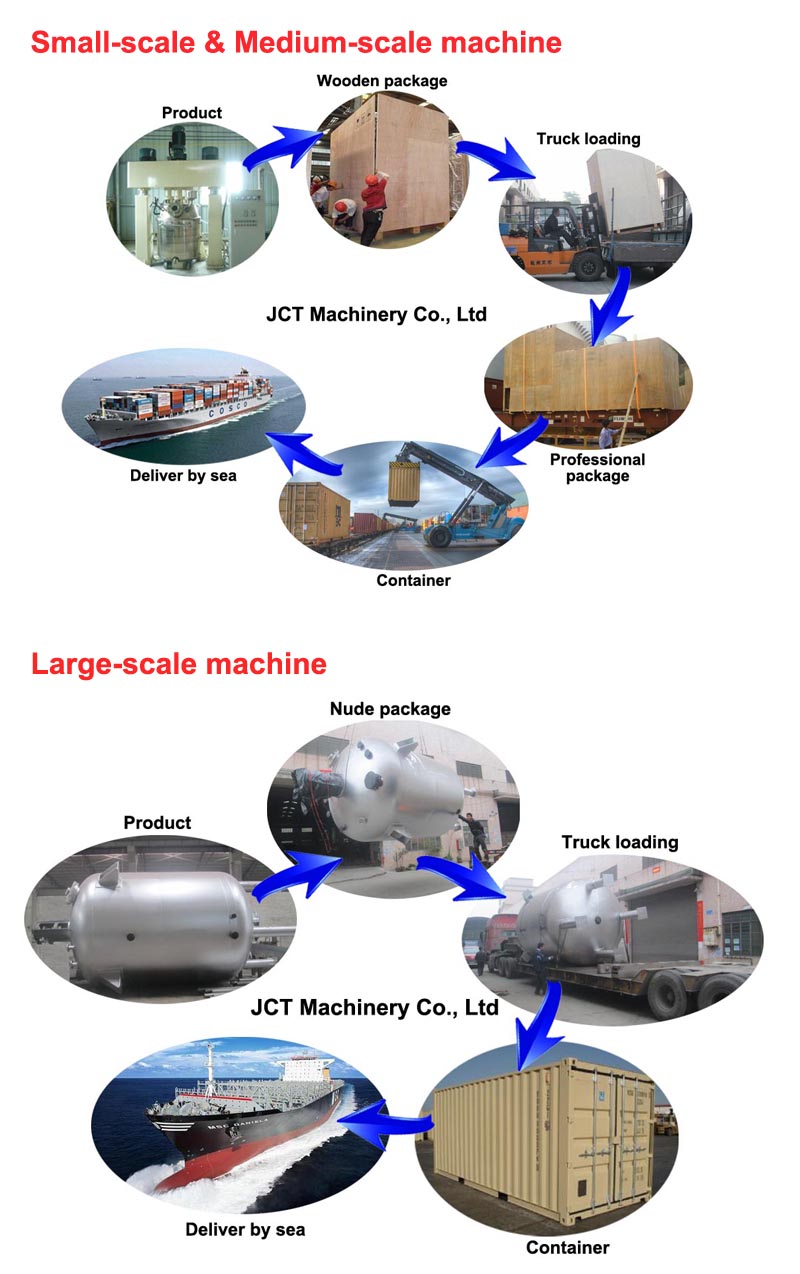

Small-scale & Medium-scale machinery for silicon sealant: wooden package-truck loading-container-shipment;

Large-scale machinery for silicon sealant: nude package-truck loading-container-shipment.

Q: Can you send the formula for the products we want to make?

A: Our machines can be used for many kinds of product making, such as Resin, Paint, Adhesive, Cosmetic, Food, Chemicals. There are many kinds of these products, so it's impossible for us to know all the formulas and technologies. We can assist you to find the raw material list you need, and after you place order with us, we can help you to find formula and technology, there will be engineers to teach you how to make the product, and the cost will be on your account.

Q: Do you have machines in stock?

A: Yes, but just the small-scale machines. Machines are different with other products, most of the large-scale machines are designed according to our customers' requirements, different customers have different production requirements, so the technical parameter is different for most machines. On the other hands, most of the our machines will cover a large area, so once the machines are finished, we will effect shipment after QC.

Q: Can you send the detailed drawings of the machine to us before we place order?

A: We can send you a draft drawing of the machines, and after you place order and pay the deposit, our engineer will design the specific technical parameters fo you and send you the detailed drawings. Once you confirm without questions, we will put it into production.

Q: Why does it take at least 20 days to finish the machine?

A: Once receipt the deposit from you, we will design the drawings and make out the list of the materials and accessories for the production. Once the drawings are finished, our workers will start the production, from welding, polishing, assembling, debugging, detection and so on. After finish, they need time to check the machines, if found any possible defect parts, they will return to the production until every part is 100% approved.

Q: Can we pay the balance after we receive the machines and test without problems?

A: It's unnessary to worry about the quality of our machines, we are confident in that. After the machine is finished, we can install and test the machine for you (if you can not come to our factory, we can record a vedio and send to you). Only after you check without problems, we will effect shipment.

Q: If you price is higher than the suppliers for the products that are not made by you?

A: We can provide the whole production lines, which include many facilities and accessories(like Oil furnace, steam boiler, etc). It's impossible for us to make everyone of them, because we just make the main machines. However, based on our great reputation in the business, and also considering our huge sourcing quantity by collecting the orders from domestic and foreign customers, and our strong cash flow to pay the suppliers in advance. We can get the best offer from the suppliers. So after adding an reasonable profit for the outsourcing facilities and accessories (like Oil furnace, steam boiler, etc), we still can offer a very competitive price similar to our suppliers, or even lower in some case.

Quality assurance & Certificates

Professional Sales team & Technology support

Workshop

1. One-stop total solution

2. Best seller ready for you

3. Refund or replacement for any product faulty

4. Low price, high quality, nice service, great credit

5. New product into our range every year

6. Exclusive desigh only from us

7. 100% quality checking before shipment

4. Our Customers

5. Contact us