pressure sensitive adhesive making machine

eyelash cyanoacrylate adhesive

1. INTRODUCTIONS OF ADHESIVE PRODUCTION LINE

NOTE: reactor is the most important part of the whole line.

Applications:

1. Adhesive: Acrylic emulsion glue, Urea-formaldehyde glue, Epoxy potting glue, Polyurethane sealant/ adhesive, Water based polyurethane, Liquid nails (Free-nail glue), etc.

2. Resin: Polyurethane resin, Polyester resin, Alkyd resin, Unsaturated polyester resin, Saturated reisn, Acrylic resin, Phenolic resin, Urea-formaldehyde resin, Epoxy resin, Amino resin, etc.

3. Paint: White latex, Water based paint, Oil based paint, Curing agent (hardener), Thinner, etc.

4. Silicone oil: Silicone oil, Scrap silicone cracking for silicone oil, etc.

Details can consult with us online OR by email!

2. TECHNICAL PARAMETERS OF ADHESIVE LINE

| TYPE |

VOLUME |

HEATING MODE |

STRUCTURE |

PADDLE STRUCTURE |

SHAFT SEALS |

MATERIAL |

REMARKS |

| FYF-100 |

100 |

1. Electric heating 2. Steam heating 3. Oil heating |

1. Jacketed structure 2. Outer pipe/ tube structure 3. Inner pipe/ tube structure 4. Outer and inner pipe/ tube structure |

Anchor Paddle Ribbon Turbine Block Dispersing disc |

1. Single mechanical seal 2. Double mechanical seal |

SS304 SS316 Q235-B |

1. The power of motors, stirring speed level determined by the actual requirements. 2. The thickness of the cylinder will be designed according to the working pressure. |

| FYF-200 |

200 |

| FYF-300 |

300 |

| FYF-500 |

500 |

| FYF-1000 |

1000 |

| FYF-1500 |

1500 |

| FYF-2000 |

2000 |

| FYF-2500 |

2500 |

| FYF-3000 |

3000 |

| FYF-4000 |

4000 |

| FYF-5000 |

5000 |

| FYF-6000 |

6000 |

| FYF-8000 |

8000 |

| FYF-10000 |

10000 |

| FYF-12000 |

12000 |

| FYF-16000 |

16000 |

| FYF-20000 |

20000 |

| FYF-30000 |

30000 |

| FYF-40000 |

40000 |

| Any other types or any other special requirements, we can specially design for you! |

3. PICTURES OF THE ADHESIVE LINE

The adhesive production line

The mixing paddle of the adhesive machine

Production line1

Production line2

Production line3

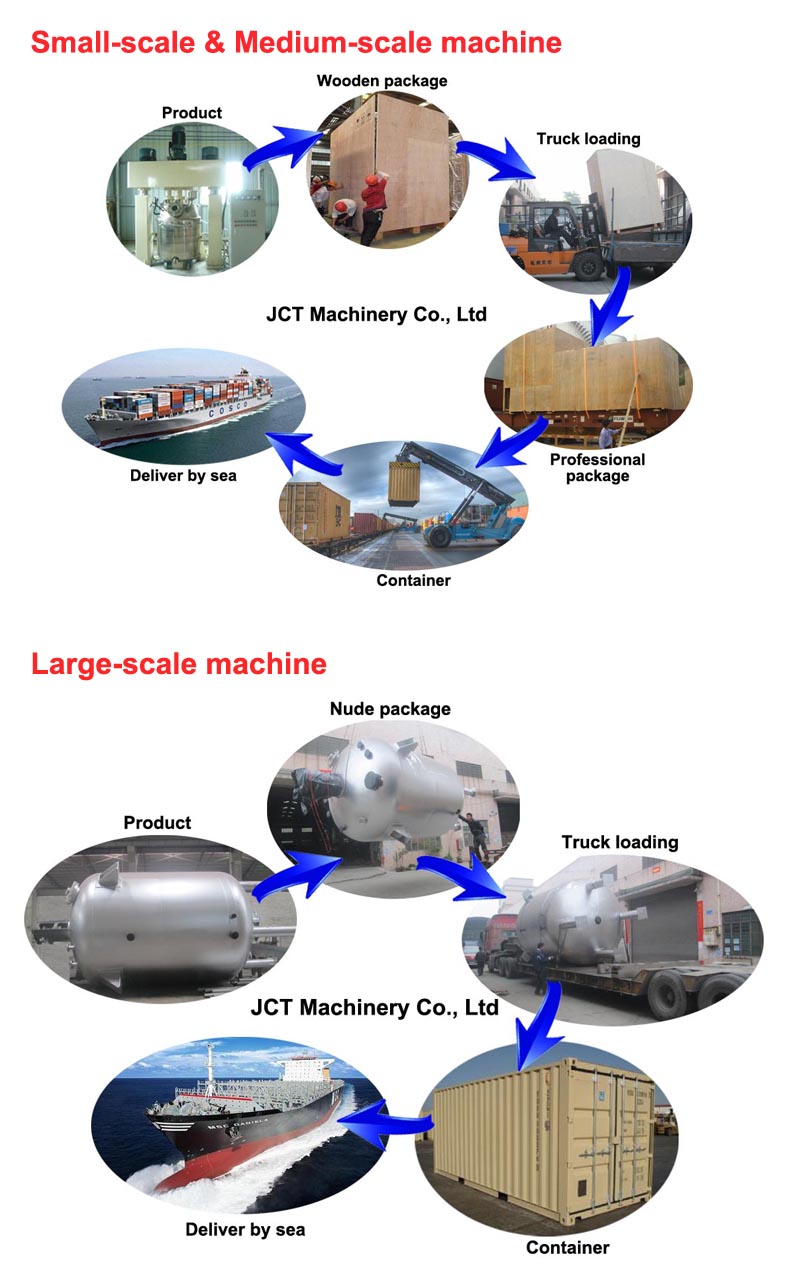

1. 100L~500L Adhesive making machine: Quality inspection - Wooden package - Truck loading - Container - Deliver by sea.

2. 1000L~10000L Adhesive making machine: Quality inspection - Plastic bag/ Film materials package - Truck loading - Container - Deliver by sea.

3. 10000L~40000L Adhesive making machine: Quality inspection - Film materials package/ Nude package - Truck loading - Container - Deliver by sea.

eyelash cyanoacrylate adhesive production line

Q: Can you send the formula for the products we want to make?

A: Our machines can be used for many kinds of product making, such as Resin, Paint, Adhesive, Cosmetic, Food, Chemicals. There are many kinds of these products, so it's impossible for us to know all the formulas and technologies. We can assist you to find the raw material list you need, and after you place order with us, we can help you to find formula and technology, there will be engineers to teach you how to make the product, and the cost will be on your account.

Q: Do you have machines in stock?

A: Yes, but just the small-scale machines. Machines are different with other products, most of the large-scale machines are designed according to our customers' requirements, different customers have different production requirements, so the technical parameter is different for most machines. On the other hands, most of the our machines will cover a large area, so once the machines are finished, we will effect shipment after QC.

Q: Can you send the detailed drawings of the machine to us before we place order?

A: We can send you a draft drawing of the machines, and after you place order and pay the deposit, our engineer will design the specific technical parameters fo you and send you the detailed drawings. Once you confirm without questions, we will put it into production.

Q: Why does it take at least 20 days to finish the machine?

A: Once receipt the deposit from you, we will design the drawings and make out the list of the materials and accessories for the production. Once the drawings are finished, our workers will start the production, from welding, polishing, assembling, debugging, detection and so on. After finish, they need time to check the machines, if found any possible defect parts, they will return to the production until every part is 100% approved.

Q: Can we pay the balance after we receive the machines and test without problems?

A: It's unnessary to worry about the quality of our machines, we are confident in that. After the machine is finished, we can install and test the machine for you (if you can not come to our factory, we can record a vedio and send to you). Only after you check without problems, we will effect shipment.

eyelash cyanoacrylate adhesive line

4. OUR COMPANY

Professional sales team & Technology assistance

Strict processing workshop

Certificates & High-quality assurance

1. Purchasing integration

2. Stricter quality inspection

3. Cheapest shipping & Professional export procedure

4. Best business experience

5. WHY CHOOSE US

6. OUR CUSTOMERS

7. CONTACT US