$1

Injection molding waterproof anti shock plastic case for multi purpose

Overview

Quick Details

Material:

Silicone, nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc.

Type:

Stretch Lid

Usage:

Jars

Feature:

Pilfer-Proof

Custom Order:

Accept

Place of Origin:

Hebei, China

Brand Name:

Baimi

Model Number:

customized

Item:

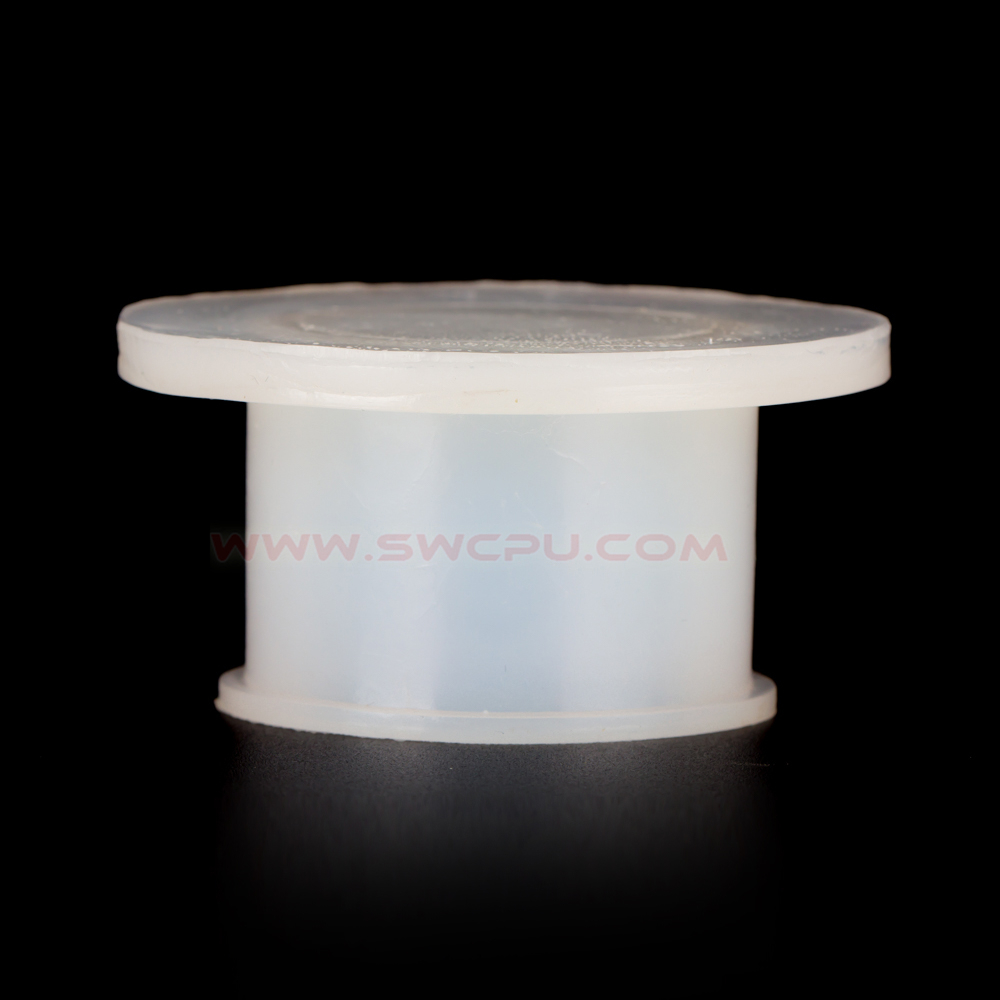

customized stretch Silicone suction Fermentation Lid

Color:

Black,white,red,green or any color according to Pantone colors

Size:

As per customer's request

Processing Technic:

CNC machining,injection molding & extrusion

Hardness:

Shore D

Working temperature:

-60~350℃

Tolerance:

±0.05mm

Density:

0.9-2.5grams per cubic centimeter

Service:

OEM or ODM

Supply Ability

Supply Ability:

50000 Piece/Pieces per Day

Packaging & Delivery

Packaging Details

In general,we use ziplock bag or bubble film plus cardboard boxes, and wooden pallets or wooden cases will be used if necessary.

Port

Tianjin,Shanghai,Guangzhou,Beijing,Qingdao and etc

Product Description

Our advantages

OEM size suit for customers' requirment

Various hardness for your choose

Multiple color can be choosed

Engraved or embossed logo accepted

Large order quantity are able to be fulfilled

Strict quality control system

In time delivery and custom-service

Item |

customized stretch Silicone suction Fermentation Lid |

| Material | EPDM, NR, Silicon, FKM, IIR, NBR, SBR, or Custom Compound |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer's requirements |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Technology | Hot pressing molding, injection molding, extrusion |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

Product Show

Related Products

Advantages

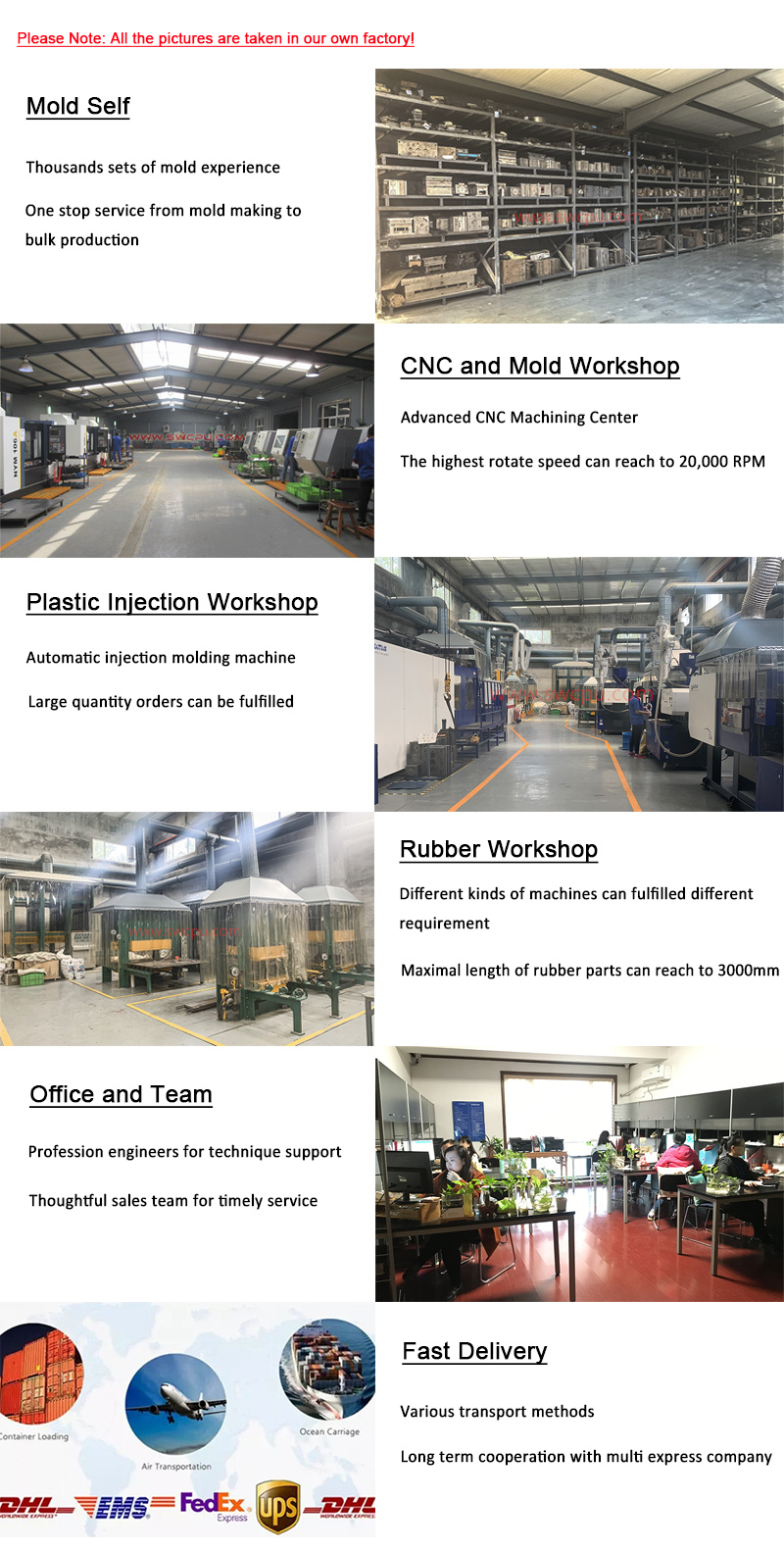

Company Information

Zhongde (Beijing) Machinery Equipment Co.,Ltd has rich experience in OEM parts, we have our own laboratary, CNC workshop, plastic injection workshop, rubber automatic workshop, printing and electro-plating workshop, which can ensure both quality and lead time.

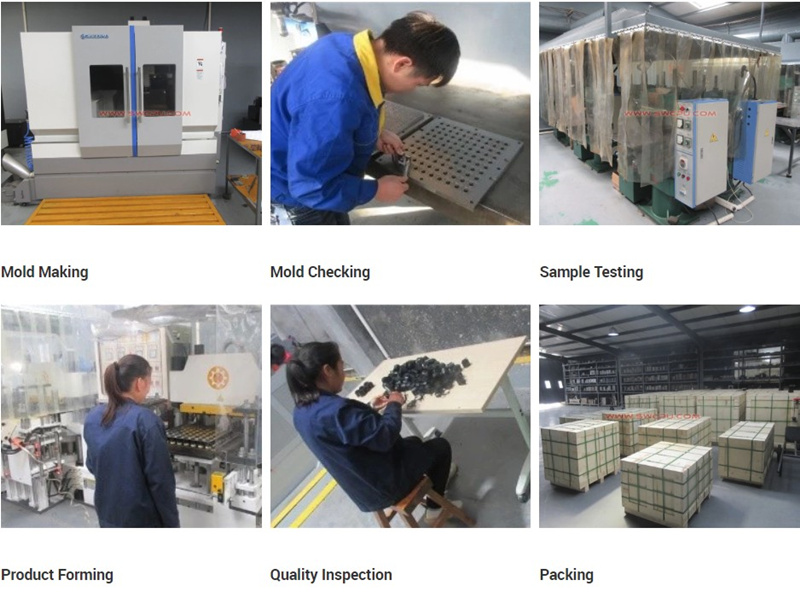

Production Flow

Recommand product

FAQ

Q1. Are you manufacture or trade company?

A: We are both, we have our own factory and we can export by ourself.

Q2. What kind of payment do you accept?

A: Trade assurance, T/T, L/C, Weston Union are all accepted.

Q3. What is normal lead time?

A: Average 15-25days for tooling, bulk orders should be depends on quantity.

Q4. What is your standard package?

A: In general we use ziplock bag or bubble film plus cardboard boxes, wooden pallets or wooden cased will be used if necessary. Special packing method is available if needed.

Q5. What is the working life of the mould?

A: It depends on the parts we made. Besides, we will maintain or replace the mould by ourselves.

Due to the difference in the purchase situation and question time of each consultant, the following responses are only valid for the questioner within 3 days, other netizens are for reference only ~

I want to consult