$1800

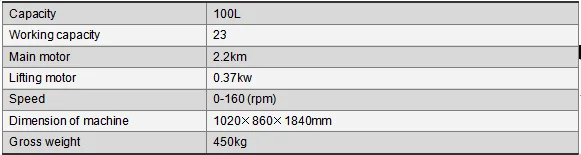

Wet magnetic separator alloy wheel vibratory pollisher

Quick Details:

Place of Origin |

Zhejiang, China |

Brand Name |

HUMO |

Condition |

New |

Power (kW) |

2.2 |

Weight (KG) |

450 |

Key Selling Points |

High Safety Level |

Warranty |

1 year |

After-sales Service Provided |

Online support, Free spare parts, Engineers available to service machinery overseas |

After Warranty Service |

Video technical support, Online support, Spare parts |

Local Service Location |

None |

Applicable Industries |

Energy & Mining, Manufacturing Plant |

Showroom Location |

None |

Keyword |

edge rounding and shinning drag finishing machine |

Application |

metal deburring and polishing |

Voltage |

220V/380V/415V/440V |

Mgnt Certification |

ISO9001 |

Usage |

Industrial Profiles |

Model |

TDG-4 |

Feature |

Environmental-friendly Fast |

Supplier Types |

Supplier |

Supplier by Area |

Asia |

Packaging & Delivery:

Supply Ability:

1000 Set/Sets per Month

Packaging Details

wooden box

Port

shanghai

Lead Time :

Quantity(Sets) |

1 - 1 |

>1 |

Est. Time(days) |

25 |

To be negotiated |

Product Description:

Function.

This machine is the latest new high-efficiency Drag finishing machine. It has the feature such as high automation degree, fine looks, easy operation, and wide range of speed adjustment, smooth running, and low noise and so on. The top of machine equip with 1 each one level and 4each two level rotating disks by K series reducer motor, it has 6teams rotatable and quick dismantled clamp on the each two level rotating disk, and it is installed automatically lift device and movable vessel. When the workpart are clamped to the rotating disk running, the vessel should be gone up to the proper position by automatically lift device, and then the process begin. Because the media is immovable, the workpart on the clamp high speed rotation by two level rotation disk, at the same time revolution by one level rotation disk, to make workpart and media cause the strong friction, and let the workpart finish grinded and polished completely. It is used in drill, milling cutter and thin workpart and medical components; it is best high- efficiency machine for cutting tool line.

Electrical system and drawing.

1. This machine adopts PLC digital control system and international brand inverter, to make workpart clamp change speed in 0~160rpm to meet different workpart demands.

Installation and adjustment.

1. a. The machine must be mounted on a flat concrete floor; four feet must touch the floor firmly.

2. b. The motor winding, the magnetizing windings and the speed windings should be tested by 500 megameter, the insulation must be over 0.38 megohm.

3. c. Start the machine and try to operate indication button, Check the earth wire, be sure that it is in good working condition to avoid any accident.

Contruction and working principle

1) Construction:

The machine is composed of rotating disk, basement, lifter for vessel, movable vessel, and electrical control box (Shown in

outline drawing).

1. a. Rotating disk: it composed of 1set one level and 4sets two levels fixed disk and rotating disk. It has 6teams clamps on the

each two levels rotating disk. When one level rotating disk run by K series reducer motor drive, 4sets two level rotating disk

whirl around one level fixed gear ring. And 6sets workpart clamp on the two level rotating disk is high speed revolution

around two level fixed gear ring, to get the high efficiency and excellent quality workpart. The rotating disk is made of good

quality steel material and equip with K series reducer motor, it is fixed to the top of machine basement.

2. b. Basement: it is welded by steel tube, it has rotating disk on the top and lifter for vessel on the bottom, and has two free

open doors.

3. c. Lifter for vessel: it is compose of the special turbine lifter and 3ets leader; the movable vessel can go up and down by

automatically control button.

4.d.Movable vessel: it is welded of steel plate. The top is octagon vessel trough for media and have valve on the bottom of vessel

trough for discharge the media. And it has 4sets rotating wheel on the bottom to keep easy and quick change media trough.

5. e. Electrical control box: it is made of single and close steel box, and install to the left of basement. Operate the machine

by buttons on the control panel.

2) Working principles:

The Drag Finishing Machine make the workpart fixed to two level rotating disk on the top, but the media trough immovable, so the

workpart can be high speed rotation and revolution by rotating disk drive,so make workpart and media cause the strong friction,

and let the workpart finish grinded and polished completely.

Due to the difference in the purchase situation and question time of each consultant, the following responses are only valid for the questioner within 3 days, other netizens are for reference only ~

I want to consult$18400

Vibratory finishing machine