Twin screw extruder is widely used in LCP granules extrusion, plastic pelletizing industry processing. Our CE/ISO verified machines already exported to more than 50 countries all over the world. High quality machines, stable operation, thoughtful service, ensure us more confidence, and won more and more trust from customers.

Twin screw extruder is widely used in LCP granules extrusion, plastic pelletizing industry processing. Our CE/ISO verified machines already exported to more than 50 countries all over the world. High quality machines, stable operation, thoughtful service, ensure us more confidence, and won more and more trust from customers.

1. Twin screw metering feeder: 1pc

2. Reduction box(gear box):

Output speed: 600rpm; Input speed: 1480rpm;

Thrust bearing: NSK brand;

Gear material: high quality 20CrNi2MoA; High speed heavy load gear face

Lubrication oil pump: 1.1kw

3. Main motor:

Y2 type 4 grades AC motor; SIEMENS BEIDE brand

Power 90-160kw; Delta inverter for speed adjustment;

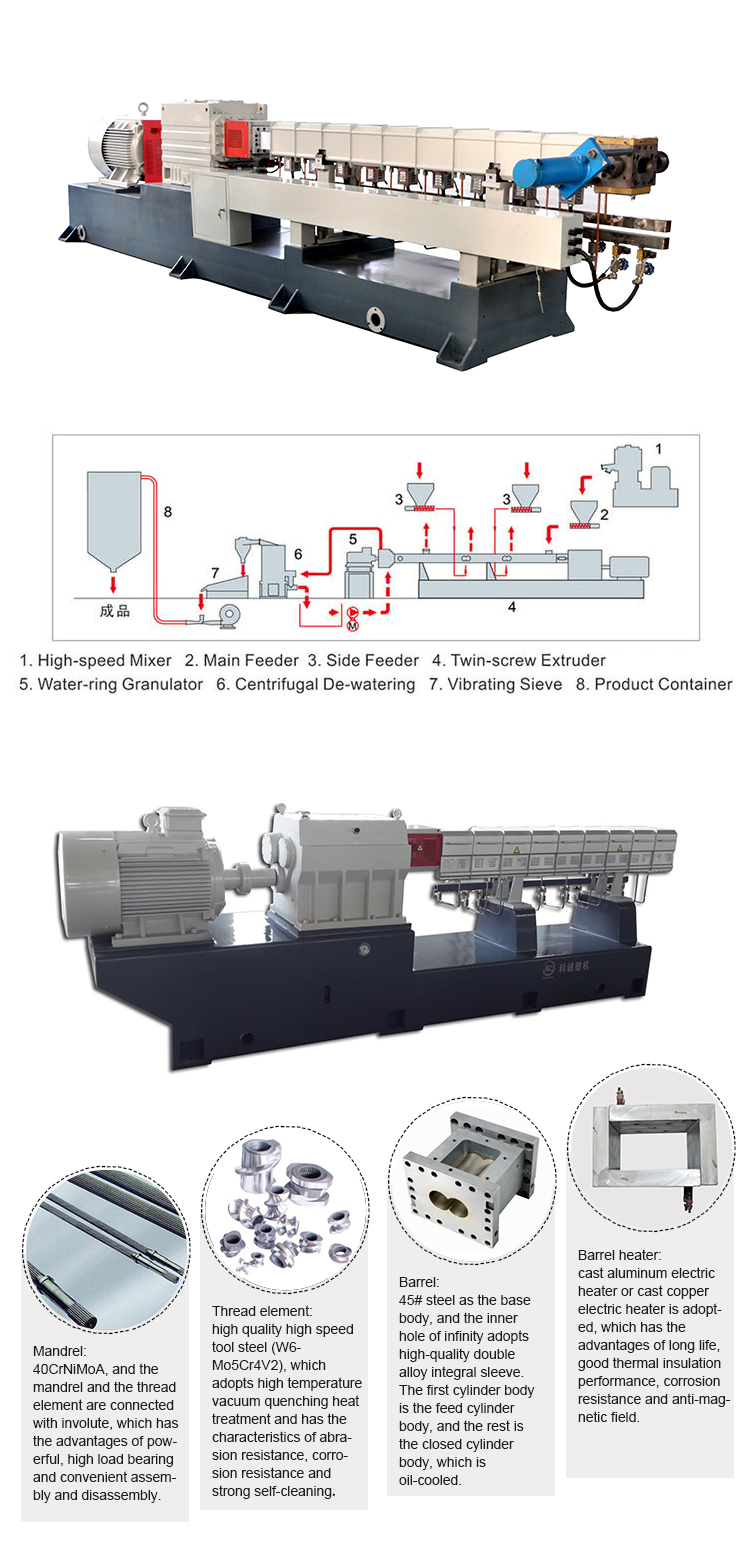

4. Screw: Module type

a. Diameter: φ71mm; L/D 36-44:1;

b. Screw elements: Material: High speed tool steel, High temperature vacuum quenched; Hardness:HRC60-64;

c. Shaft:Material:40CrNiMoA, hardness HB300-350

Involute spline pivot and screw elements assembly, ensures uniform share of high torque;

Counter-clockwise thread fastening ends for the screw elements sustaining;

5. Barrel:

a. Frame: Bi-metalic C type interlayer, wear-resistant and corrosion-resistant

b. Barrel sections, 290mm/section, Open barrel: 1st for feeder adaptor

c. Cooling medium:Water cooling;

d. Heating medium: cast Aluminum Heater;

6. Soft water cooling system

a. Water pump motor: 0.75kw;

b. Separately water tank for easy cleaning and maintenance;

c. Controlled by needle valve, Taiwan CS high-precision automatic control magnetic valve

d. Piping material: stainless steel, φ60mm;

e. Connection between barrel and main piping is copper tubes.

f. Heat exchanger model: LS-415, 1.7 m2

Our R&D team can provide strong support for you. Before sales, welcome to consult any questions about machines, we'll figure out the specifications you need, and help you to make right decisions. After sales, we'll manufacture machines according to your requirements exactly, and deliver products to you in time. Also our factory will sent engineers overseas for installation, testing as well as training.

TYPE |

D(mm) |

L / D |

N(r/min) |

P(kw) |

T(N/m) |

T/A3 |

Q(kg/h) |

| KC-20 |

21 |

32-48 |

600 |

4 |

30 |

4.8 |

2-10 |

| KC-30 |

30 |

32-48 |

500 |

7.5 |

85 |

4.8 |

10-30 |

| 600 |

11 |

85 |

4.8 |

10-40 |

| 500 |

15 |

110 |

6.2 |

15-55 |

| 600 |

18.5 |

140 |

8 |

30-75 |

| KC-36 |

35.6 |

32-48 |

600 |

18.5-22 |

125 |

4.6 |

30-75 |

| 600 |

30-37 |

225 |

8.3 |

40-100 |