$700000

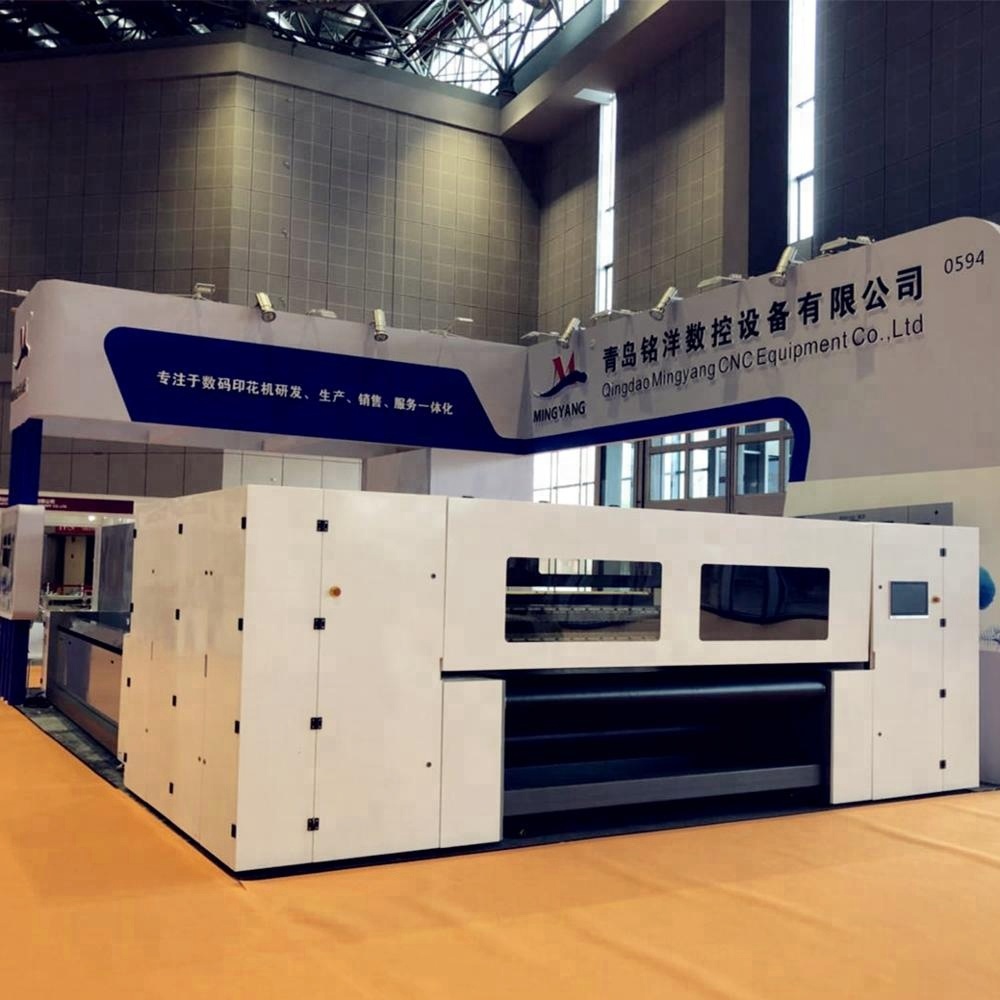

MINGYANG Fabric Digital Printing Machine – Textile Printing Machine

Quick Details

Condition:

New

Place of Origin:

Shandong, China

Brand Name:

MINGYANG

Dimensions(L*W*H):

4000/5500*2500*2000mm

Plate Type:

Digital belt textile fabric printer

Weight:

3000~4500KG

Automatic Grade:

Automatic

Color & Page:

MULTICOLOR

Certification:

CE Certification

Usage:

Cloths Printer, Textile Printer

Voltage:

AC380V or other requirements

Applicable Industries:

Garment Shops, Manufacturing Plant, Fabric printing plant

Warranty:

1 YEAR

After-sales Service Provided:

Online support, Field installation, commissioning and training

Print Dimension:

W: 3.2m L: unlimited

Ink Type:

Aqueous inks

Name:

Cotton and Polyester Fabric Printer Digital Textile Printing Machine

Printing Material:

Cotton, linen, viscose, mixed cotton, polyester, wool, silk, nylon

Ink type:

Reactive/pigment/sublimation/disperse/acid ink, etc

Print head:

Starfire sg1024, etc

Color:

Standard 4/6/8 colors

Parts brand:

Original Habasit belt, Yaskawa servo motor, THK guide rail

Print speed:

60~480sq.m/h

Application:

Textile printing machine on garment, scarf, flag, bed sheet, T-shirt

Shandong Qingdao factory:

Original digital fabric printer equipment manufacturer

Type:

Digital textile fabric printing machine

Supply Ability

Supply Ability:

40 Set/Sets per Year

Packaging & Delivery

Packaging Details

The standard package for roll to roll digital fabric printing machine textile printer equipment is wooden pallets polywood boxes, inner PE stretch film for water-proof.

Port

Qingdao, CHINA

Lead Time :

Shipped in 0 days after payment

MY1800T Automatic Digital Printing Machine for Cotton Fabric – Multicolour Fabric Printing with Digital Belt and Aqueous Inks – Available at Achasoda.com

Digital Textile Printing Machine Application

Manufactured by Mingyang CNC Equipment Co., Ltd, specialized in research and maufacture of industrial belt digital fabric printer digital textile printing machine for stable industrial production, the textile printer can dtg print all types of fabrics with any design, used to make clothes, apparel, garment, (for children, for wedding, for sports wears, for camouflage clothing, for saree), flag, scarf, home textile, blanket, carpet, leather, PU, house drapery and decorations, advertisement, Polyester (elastic or inelastic, sublimation printing or disperse printing), PP, leather, non-woven, silk, nylon, chiffen wool, advertisement, for individual, diversified producing. With high control system and high printing precision, it will be became the popular new printing machines in the textile industrial fields all over the world.

1.Automatic belt system, belt automatic cleaning, heating, adjusting system.

2.Automatic fabric feeding and taking up system with sensors.

3.Machine main parts are from the countries of origin, best quality with high precision, etc.

4.Optimized print heads for various print designs. Starfire sg1024 128head*8colors can reach 900sq.m/h, Kyocero KJ4B 64heads*8colors can reach 900qd.m/h or more faster suitable for volume production.

Digital textile printing solutions are mainly for what kind fabric material choose which kind of inks and how, of course, it is not fixed or 100% correct best solution, same fabric may be have another better solution. We provide the samples printing services, for save time and trip cost and for better comparasion.

1, For cotton, viscose and linen

A.Reactive direct printing, need coating, procedures like coating, printing, steaming, washing and sizing.

B.Pigment direct printing, no coating, procedures like printing, steaming and sizing.

2, For mixed cotton and polyester

A. Pigment direct printing, no coating, procedures like printing, steaming and sizing.

3, For chiffon

A.Sublimation direct printing, need coating, procedures like coating, printing, steaming, washing and sizing.

B. Disperse direct printing, need coating, procedures like coating, printing, steaming, washing and sizing.

4, For polyester

A. Heat transfer, no coating, firstly print on sublimation paper and then heat transfer on polyester.

B. Sublimation direct printing, need coating and printing, then color fixation.

5, For wool, silk

A. Reactive direct printing, need coating, procedures like coating, printing, steaming, washing and sizing.

B. Acid direct print, need coating, procedures like coating, printing, steaming, washing,and sizing. (Seldom)

6, For Nylon

A. Acid direct print, need coating, procedures like coating, printing, steaming, washing and sizing.

Due to the difference in the purchase situation and question time of each consultant, the following responses are only valid for the questioner within 3 days, other netizens are for reference only ~

I want to consult