Fire baked clay brick insulating bricks for pizza oven

Product details

Fireclay brick Al2O3 content is 30%-48%, SiO2 content is 50%-65%, etc. Its refractoriness is 1580-1750°C, refractoriness under load is 1250-1450 °C.

Raw Material Selection

To ensure the quality of our raw materials, we only purchase raw materials from our long-term trusted suppliers. With every purchase, the raw material must be passed 2 times inspection, 1 time at our supplier's site. a second inspection on the batch after the material arrived to our factory. Each time raw materials enter our facility, they are inspected again prior to being accepted.

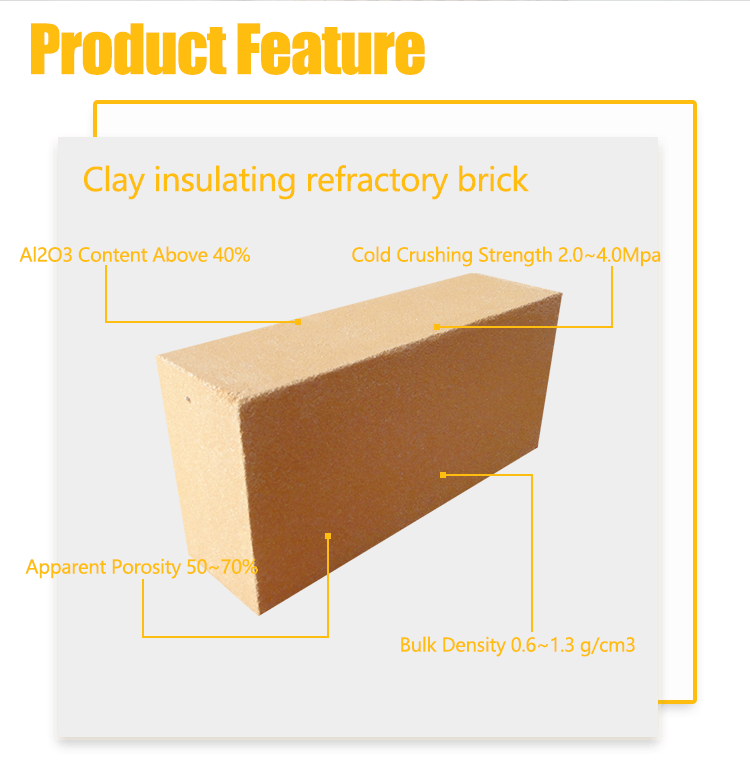

Feature

1. High refractoriness, high-temperature endurable.

2. Good thermal shock resistance.

3.Good volume stability at high temperature.

4. Good corrosion resistance.

5. Good spalling resistance and wear resistance.

6. High mechanical strength.

7. High-temperature creep rate is low.

Technical data

Item |

Fireclay Insulating Brick |

0. 6 |

0.8 |

1.0 |

1.3 |

Al2O3 (%) |

40 |

40 |

40 |

40 |

Fe2O3 (%) |

1.5 |

1.5 |

1.2 |

2 |

SiO2 |

55 |

55 |

55 |

55 |

Bulk Density (g/cm3) |

0.6 |

0.8 |

1.0 |

1.3 |

Apparent Porosity % |

70 |

60 |

55 |

50 |

Cold Crushing Strength(Mpa) ≥ |

2.0 |

2.5 |

3.0 |

4.0 |

Reheating Linear Change (%)°C X 12H ≤ |

1300℃ -0.5 |

1350℃ -0.5 |

1350℃ -0.9 |

1350℃ -0.9 |

Thermal Conductivity(W/m.k)(1000°C) |

0.33 |

0.60 |

0.45 |

0.8 |

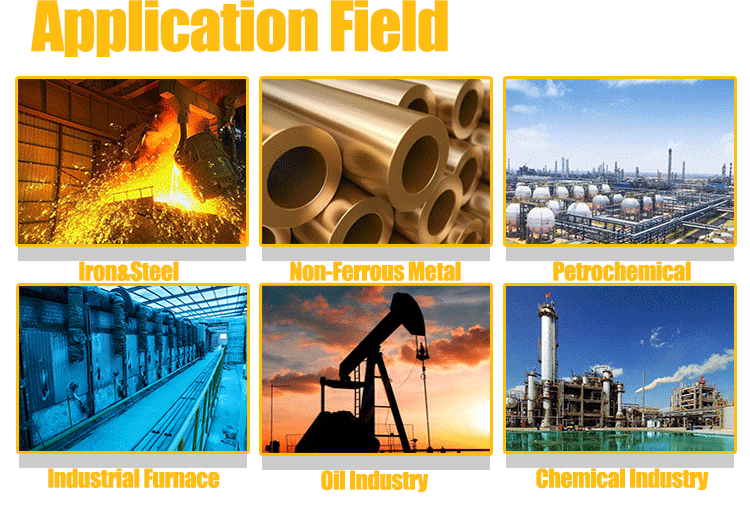

Application

They are primarily used for furnaces and kilns in metallurgy, steel, power, chemical industry, and electric power and machine building etc areas.

Packaging and shipping

1. Strong packing will protect the goods from any possible damage during transit.

2. Solid packing and overall stuffing can prevent the cases from vibration and jarring.

3. We must take necessary precaution that the packing can protect goods from pilferage or rain.

4. We can confirm that we take every possible precaution to ensure that our products reach our customers all over the world in prime conditon.

1. Carton packaging .

2. tray + plastic film + fixed band .

3. pallets: 1*1m,0.93*0.93m .

4. tray weight: 1.6~2.0ton.

5. packaging according to customer service requirements .

Our service

1. when you inquire our product or price, we will reply you within 8 hours.

2. Well-trained and experienced technician answer all your questions in fluent English.

3. We provide the best after sales service. All our products have 1 year warranty period.

4. Offering the support to solve the problem in the selling or application period.

5. Competitive prices based on superior quality.

6. Guarantee samples quality same as your ordering production quality.

7. Adhere to the business philosophy "mutual trust, mutual benefit, mutual profit, faith oriented".

8. We believe "customer is God, quality is our unchangeable commitment".

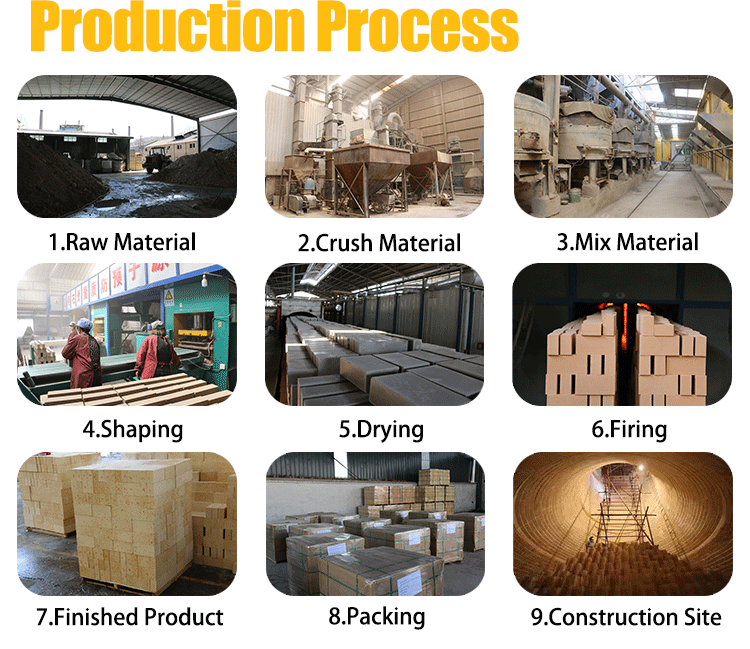

Production Process

Quality Assurance

Lite Refractory is committed to high quality standards for all its products and services. With its thirst on State of the art technology at every level and a wide range of products, Lite Refractory can provide ideal solutions for the stringent requirement of the customer. Backed by decade of experience in different industries, and close association with customers,Lite Refractory will always bring new products which will give better life and value to the user.

The quality assurance system consists of the following steps:

a.Inspection and Control of incoming raw materials:According to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

b.Inspection and control of the process:During the production,every brick will be weighed twice strictly to reduce the error of weight .

c.Inspection of product Standardization of quality of each product by process control and experimentation.

d.Taking corrective measures whenever deviations are noted.

e.Quality audit by quality management.Before delivery, the inspectors will inspect the size,appearance,physical and chemical properties of brick again in factory.

Henan Lite Refractory Material Co., Ltd is located in Zhengzhou Henan province,which is one of the main refractory production bases in China.

Our manager has been engaged in refractory material industry for more than 15 years.In the technological team there are more than 10 senior designers and engineers,more than 20 technicians.

Why Choose Us?

(1)Product:

1.Based on rich refractory raw materials and experienced refractory manufacture factories,can providecomplete refractory in Specification and Category with good quality and competitive price.

2.Larger production capacity(3000tons per month) ensure the fast production cycle after confirmed the order.

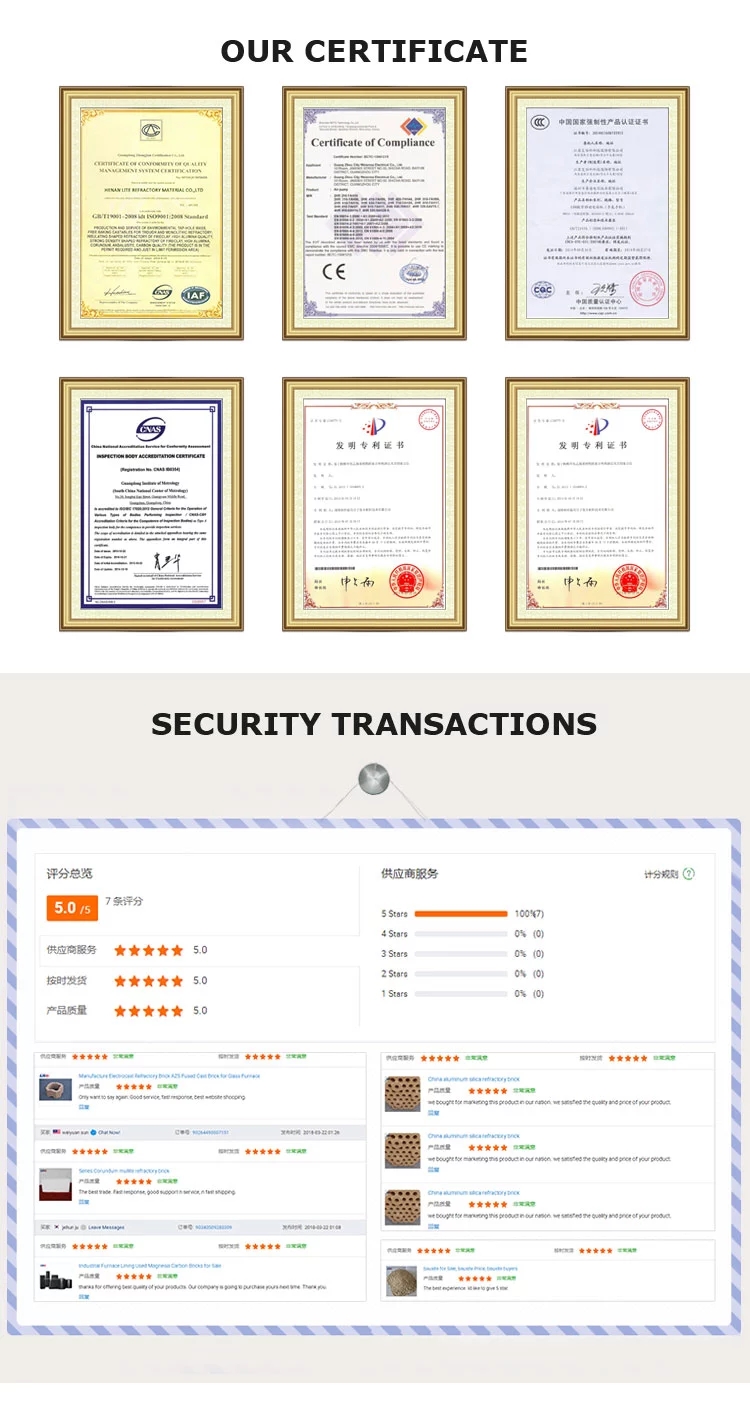

3.ISO9001 Certificate,100% QC inspection Before Shippment,and 1 year Quality Assurance.

4.Professional packing avoid damage;Competitive Price make the products competitive in customers' market.

(2)Service

1.Alibaba Assessed 5 years Gold Supplier,but we have exported from 2010 through other trading companies and our manager is engaged in refractory materials more than 15 years,can supervise raw material,production,quality control,package,delivery professionally to ensure the products' quality.

2.Sales person:

(1)Quick and Professionally reply:Engaged in international trade more than 4 years with rich experience,can provide customers a series of advices and solutions including products,package,transportetc to make customer worry-saving and save time.

(2)Provide customer more than 8 hours'consultation service.

3.Free samples.Produce the products according to clients' requirements. To meet the refractory solutions, also can arrange technicians to customers' plant if needed.