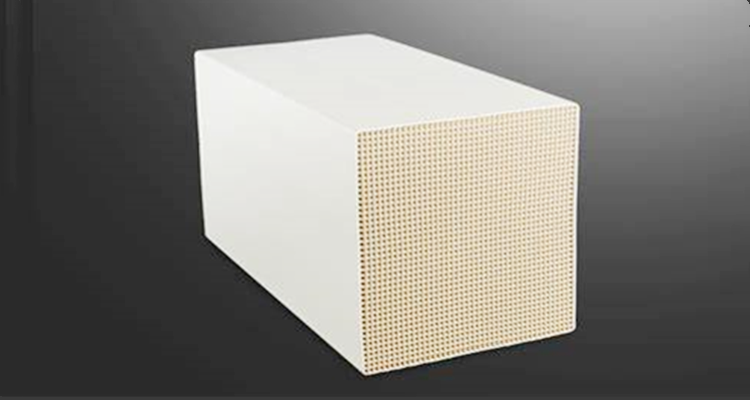

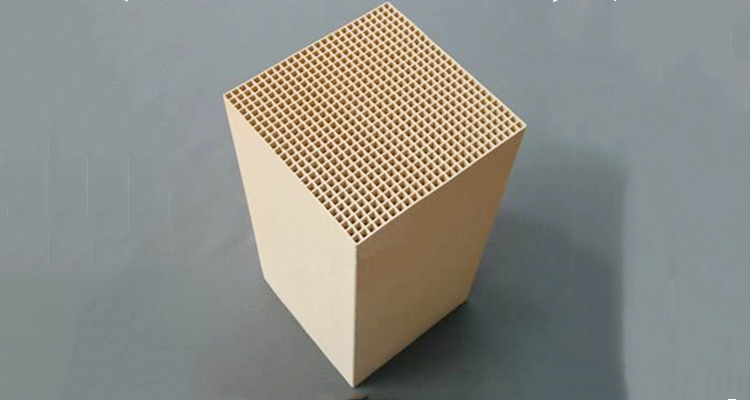

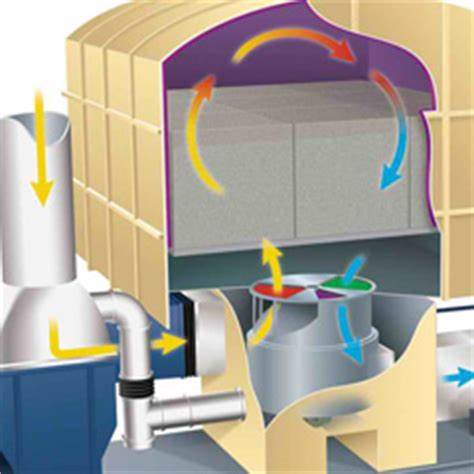

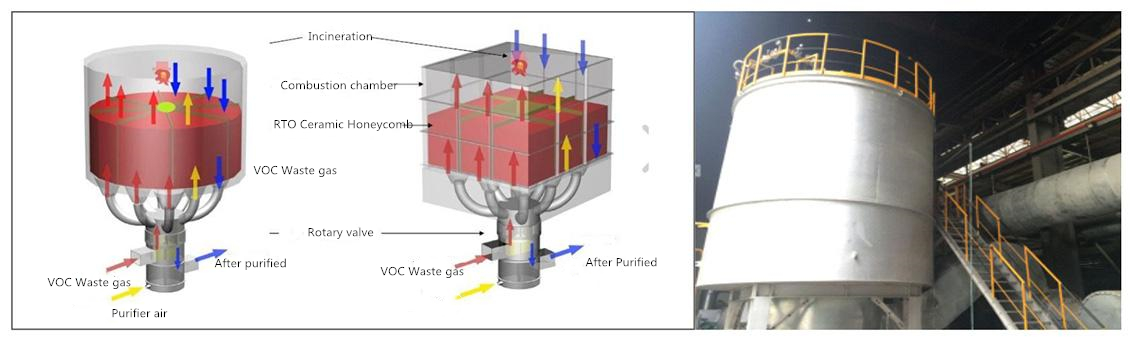

The RTO achieves emission destruction through the process of high temperature thermal or catalytic oxidation, converting the pollutants to carbon dioxide and water vapor while reusing the thermal energy generated to reduce operating costs. RTO Units use two primary medias: JINTAI Ceramic Honeycomb Monoliths and Ceramic Saddles. Each of these products offers excellent heat capacity, thermal shock, and chemical resistance properties for use in RTO units. Ceramic Honeycomb Monoliths are specified as structured RTO media and Ceramic Saddles are a form of random RTO media.

Ceramic Honeycomb Materials: Cordierite, Porcelain, Mullite, Alumina, Stoneware, etc.

Regenerative Thermal Oxidizers are used to destroy Hazardous Air Pollutants (HAPs), Volatile Organic Compounds (VOCs) and odorous emissions that are often discharged from industrial processes. The RTO achieves emission destruction through the process of high temperature thermal or catalytic oxidation, converting the pollutants to carbon dioxide and water vapor while reusing the thermal energy generated to reduce operating costs. RTO Units use two primary medias: JINTAI Ceramic Honeycomb Monoliths and Ceramic Saddles. Each of these products offers excellent heat capacity, thermal shock, and chemical resistance properties for use in RTO units. Ceramic Honeycomb Monoliths are specified as structured RTO media and Ceramic Saddles are a form of random RTO media.