$3000

Fully Automatic Brick Maker Machine – Local Block Making Machine

QT10-15 Automated brick making machine which makes fly ash brick cement cubes; features the following:

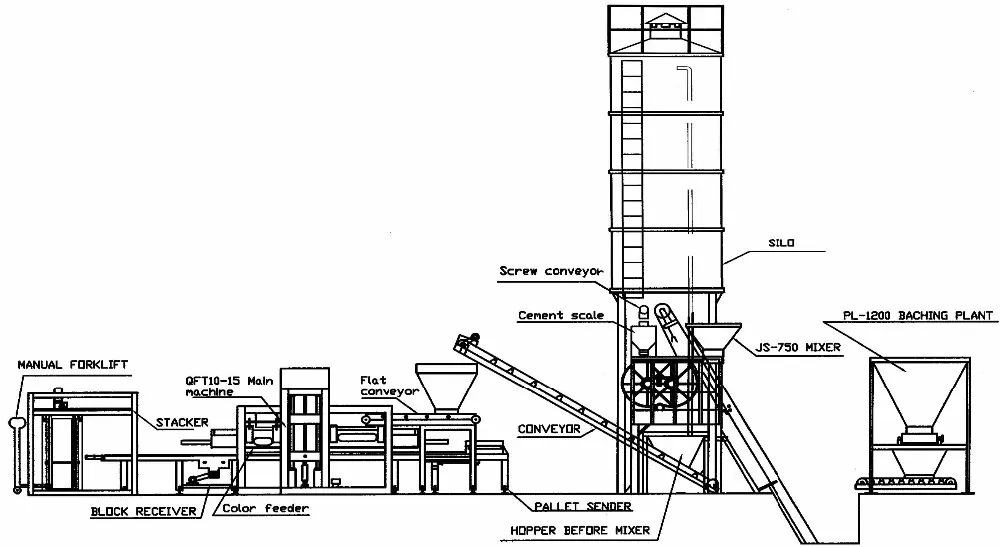

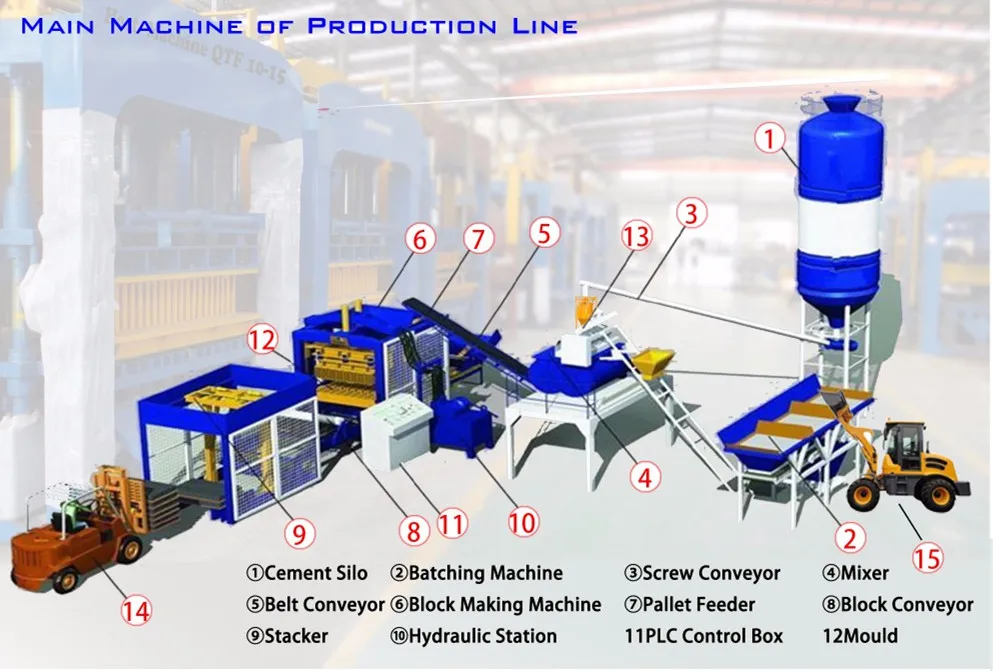

Batching Plant: This is the starting point of this manufacturing process. It is made of three loading containers along with also a weighing bin.

Additionally, it incorporates belt conveyers to carry stuff from loading bins into the weighing bin. Batching and weighing are accomplished by the PLC controller.

We could load three distinct varieties of stuff in the loading bin.

Concrete Mixture Machine: Each of the ingredients is mixed within this blending machine. PLC commands the blending time and rate. The built-in water-pump adds water into the mixture mechanically, as a requirement.

Block mold machine: This is the key to the production line. It can press the mixed material. It can make the various hollow block, solid brick, paver brick, and kerbstone.

Screw Conveyor (Optional fitment): loading bins of the This is instrumental for transporting Fly Ash from the silos(optional fitting) or cement hopper (optional fitting) to the Batching Plant.

Conveyer-belt: Once the batching plant weighs bin trips in line with this PLC controller, the material arrives for the conveyer belt. The cloth is then transported into the Mixture Machine.

Stacker: Stacker can be applied to place the cube. It is highly efficient and labor-saving.

Features of qt10-15 Automated Cement bricks Machine/road brick/insulated concrete cubes QT10-15:

Standard steel and unique welding technology

PLC control unit: JAPAN MITSUBISHI electric

Fragrant combine: TAIWAN JIUGANG

Alter: JAPAN OMRON

Electric components: FRANCE SCHNEIDER

Mold: Warm carburizing heat therapy

Host machine and machine engine: GERMANY SIEMENS

Quick Details

Applicable Industries:Building Material Shops, Manufacturing Plant, Construction works , building machinery

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Egypt, Viet Nam, Indonesia, Mexico, Thailand, Malaysia, Chile, Bangladesh

Showroom Location:Egypt, Thailand, Sri Lanka, Bangladesh, South Africa

Condition:New

Type:Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

Brick Raw Material:CONCRETE

Processing:Brick Production Line

Method:Hydraulic pressure

Automatic:No

Production Capacity (Pieces/8 hours):800-3000pcs/hr

Place of Origin:Shandong, China

Brand Name:DONGYUE

Voltage:380V/440V/415V/220V

Dimension(L*W*H):3500*2220*2850mm

Certification:CE/SGS/ISO9001

Warranty:1 YEAR

After-sales Service Provided:Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Engineers available to service machinery overseas

Key Selling Points:Full Automatic& Large Capacity

Brick size:400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Marketing Type:New Product 2020

Warranty of core components:1 YEAR

Core Components:PLC, Pressure vessel, engine, Gear, Motor, pump, Bearing, Gearbox

Supply Ability

Supply Ability:700 Set/Sets per Month automatic fly ash hollow brick making machine

Packaging & Delivery

Packaging Details

SUITABLE FOR SEA TRANSPORTATION

Port

QINGDAO

the size of pallet:

1300*900*30mm

QT10-15 Full automatic block paver brick block making machine can produce various solid blocks, hollow blocks, pavers, and curbstones by changing molds.

Full automatic block paver brick block making machine adopt to hydraulic pressure molding system, so the brick machine has more stable and higher-efficiency working status and the bricks produced are of better quality, larger density, and higher strength.

Precise line cutting technology and carburizing treatment technology to prolong mold life and increase the precision of the block.

Switches will use Japan Omron or France Schneider band, the motor will use Siemens or ABB brand.

Detailed Images

Due to the difference in the purchase situation and question time of each consultant, the following responses are only valid for the questioner within 3 days, other netizens are for reference only ~

I want to consult