These supplies, also known as emergency PSUs or back-up PSUs in the automotive world, according to Power Integrations’ product marketing manager Edward Ong, are necessary for the main traction inverter to pass ISO26262 functional safety requirements.He said that an electric vehicle typically has a 400V battery from which the main three phase traction inverter delivers power to the car’s motor, but power for the traction motor inverter’s controller and transistor gates comes from a 12V battery (see diagram left).

A separate 400V to 12V battery charger (not shown in the diagram) keeps the 12V battery charged.Should the charger or battery suddenly fail, something has to keep the traction inverter powered for the vehicle to be functionally safe and this, said Ong, falls to the safety power supply. The safety PSU runs all the time the vehicle is in operation, delivering a little less than the expected battery voltage to the ’12V’ battery rail via an OR-ing circuit (shown as a simple connection in the diagram). As such, no power is delivered by the safety dc-dc unless the battery voltage dips, at which point the safety converter immediately takes over supplying the 20W – 30W needed by the traction motor control circuit and gates.

According to Ong, automotive companies need the emergency dc-dc to run from a voltage range far wider than the normal span of the 400V battery, requiring operation from 30Vdc to 550Vdc. The converter also has to have galvanic isolation between input and output, and operate at high temperature.To meet the requirements of a safety converter, Power Integrations has based the design of its InnoSwitch3-AQ, as it will be known, on its existing InnoSwitch3 system-in-package, normally a mains-to-dc converter operating across 120Vdc (80Vac) to 420Vdc.

Inside this family of ICs are a primary-side controller chip, a primary-side power mosfet and a secondary-side controller chip – with an external mosfet if secondary synchronous rectification is needed. Operation is multi-mode quasi-resonant continuous-conduction fly-back.The two controllers communicate over a bi-directional inductively-coupled isolated link within the package – no opto-coupler is required across the isolation barrier.“To meet 30Vdc to 550Vdc we had to make circuit upgrades,” said Ong. “We tried to keep as much as possible the same: the secondary controller is the same, but there are changes in the input stage, the primary controller configured differently.”

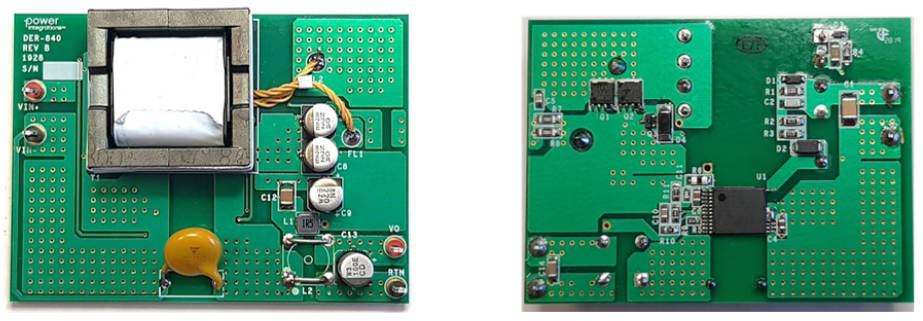

The -AQ version has a 750V internal mosfet and is qualified to AEC-Q100.400V is sufficient for current electric cars, but not the 800V batteries used in some commercial vehicles, said Ong, who also sees 800V batteries migrating into cars to improve charge times.Currently, the InnoSwitch family maxes out with 900V mosfets, while an 800V fet dc-dc will need a mosfet rated at ~1.5kV once transients and de-rating is taken into account.For operation from the high voltage supplies found in industrial three-phase mains systems, Power Integrations has already developed a way to cascode-connect an external high-voltage mosfet to the chip family – a concept that it brands ‘StackFet’. It has prepared a reference design based on InnoSwitch3-AQ and a 650V cascode mosfet for 800V (30 – 921V) automotive use (DER-859Q), and a second for 400V batteries (DER-840Q top photo). The penalty paid for the extra mosfet is a 3-5% reduction in efficiency and higher no-load consumption, which stays under 100mW, said Ong, who pointed out that the same PCB can be used for either design.

Max output at 30Vin is only 10W, rising to 20W at 60Vin, then up to 30W. No load consumption in the 400V version can be as low as 15mW, according to the company.A third reference design, DER-907Q, covers a 20W 400V PSU with a panar transformer.Is the company going to put a higher voltage mosfet inside the package to do away with the external transistor for 800V batteries?“We are looking into it,” is all Ong would say.

Source: This news is taken from www.electronicsweekly.com